Universal milling machine is a multi-purpose metal processing machine tool. It can perform vertical and horizontal milling, drilling, boring, gear cutting, and machining various complex surfaces. With high rigidity, stable performance, and easy operation, it is widely used in machinery manufacturing, mold processing, auto parts, and hardware production.

Order(MOQ) :

1Product Origin :

ChinaColor :

CustomizedShipping Port :

QingdaoLead Time :

30Weight :

3850KgFeatures

High Precision Heavy Duty CNC Gantry Machining Machine for Efficient Machining

1.The swiveling worktable (±45° rotation) and versatile spindle system enable vertical, horizontal, helical, and complex contour milling, making it ideal for gears, splines, and precision components.

2.Constructed from high-grade cast iron with stress-relieved treatment, the machine delivers exceptional rigidity, ensuring stable performance and consistent accuracy even under heavy-duty cutting loads.

3.Compatible with a variety of cutting tools (end mills, face mills, angle cutters) and suitable for processing carbon steel, alloy steel, cast iron, aluminum, copper, and non-ferrous metals.

4.Intuitive control handwheels, clear feed rate adjustments, and a well-organized control panel allow operators to quickly set up and execute machining tasks with minimal training.

5.A centralized lubrication system ensures smooth operation of all moving parts, while a robust structure and high-quality components reduce downtime and extend service life.

6.The machine can be retrofitted with a CNC control system, transforming it into a semi-automatic or fully automatic machining center for high-volume, precision production.

specification

| Specification | Unit | X6140 | X6132 | X6132B | X6132H | X6132BH |

| Table size |

mm |

1700*400 | 320*1325 | 320/1600 | ||

| No.of T-slots | 3 | |||||

| Width of T-slots | mm | 48 | ||||

| Max.load | Kg | 800 | ||||

| Longitudinal travel(manual/auto) | mm | 900/880 | 700/680 | 900/880 | 700/680 | 900/880 |

| Cross travel(manual/auto) | mm | 315/300 | 255/240 | |||

| Verical travel(manual/auto) | mm | 350/330 | 320/300 | 410/390 | ||

| Rapid feed speed | mm/min | X:2300 Y:2300 Z:770 | ||||

| Table feed range(XY/Z) | mm/min | 23.5-1180/23.5-1180/8-394 | 23.5-1180/23.5-1180/8-394 |

|||

| Spindle speed range | r/mm | 30-1500 | 30-1500 | |||

| Spindle speed step | steps | 18 | 18 | |||

| Distance between spindle axis and table surface | mm | 30-380 | 30/350 | 30/440 | ||

| Power of spindle motor | Kw | 11 | 7.5 | |||

| Overall dimension(LxW×H) | mm | 2556*2159*1770 | 2294*1770*1610 | 2294*2050*1610 | 2294*1770*1790 | 2294*2050*1790 |

| Net weight | Kg | 3850 | 2950 | 3040 | 3150 | 3240 |

Product Advantages

Why choose us

Community charging overall solution covers all application

Mature And Stable Technology

Mature And Stable Technology

Support Customized Solutions

Support Customized Solutions

Complete After-sales Service

Complete After-sales Service

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing.

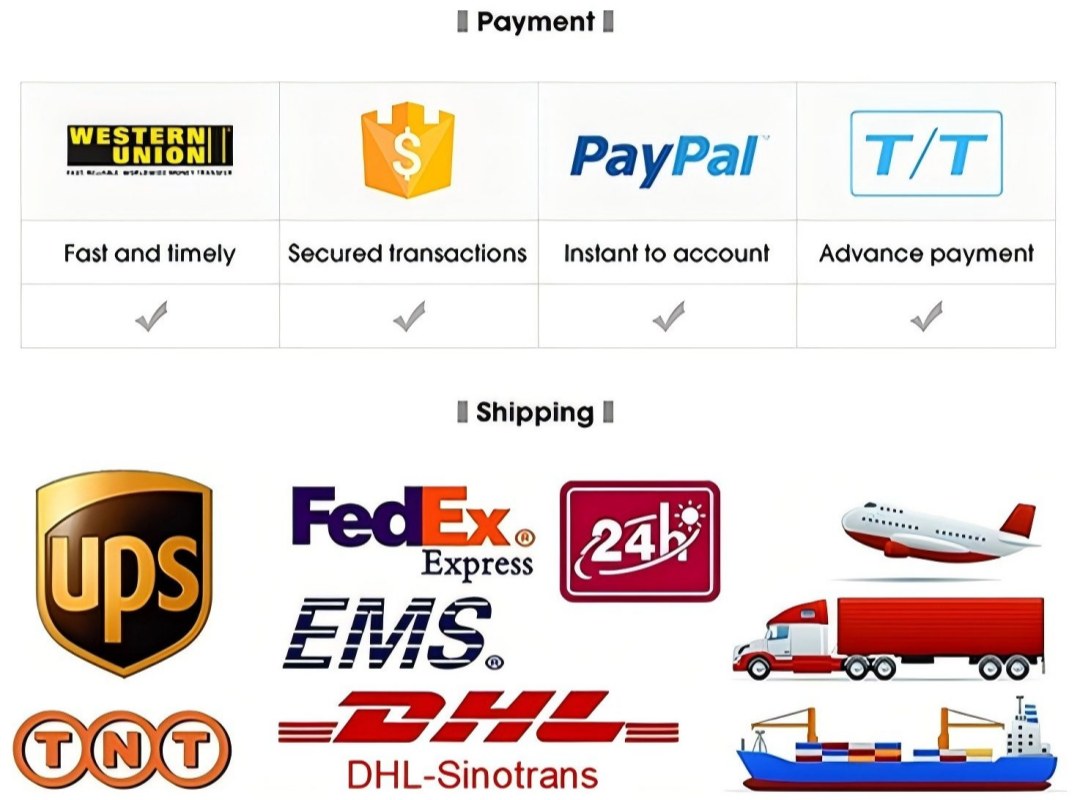

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

1.What is the difference between a universal milling machine and a vertical milling machine?

2.What materials can be processed with this universal milling machine?

3.Can this universal milling machine be retrofitted with a CNC system?

4.What are the common safety precautions when operating a universal milling machine?

Leave A Message

Scan to Wechat/Whatsapp :