The 4H turret milling machine is a medium-sized vertical manual milling machine that combines versatility, high precision and a compact structure. This model is characterized by the Taiwan turret milling head as its core technology feature. The spindle can rotate 90° left and right and 45° forward and backward, and the swivel arm can rotate 360° in all directions on the horizontal plane, significantly expanding the processing range. It is a classic general-purpose equipment for mold workshops, maintenance sections, and teaching and training fields.With quick tool change capability and flexible CNC programming, it is the perfect solution for mold making, prototype development, R&D departments, and repair workshops, responding swiftly to complex machining tasks.

Order(MOQ) :

1Product Origin :

ChinaColor :

CustomizedShipping Port :

QingdaoLead Time :

30Weight :

84TonFeatures

High Precision Heavy Duty Turret Milling Machine for Efficient Machining

1.The body is made of Mihana high-grade cast iron, which has undergone annealing and aging treatment. The structure is strong and does not deform, ensuring excellent stability even after long-term use. The three-axis angle nut is made of phosphor bronze PBC-2, which has excellent wear resistance and significantly extends the service life of the machine tool.

2.The main shaft is forged with chromium molybdenum alloy steel, after heat treatment and precision grinding, with the combination of precision bevel Angle ball bearings, the radial runout is less than or equal to 0.01mm, the cutting force is strong and the precision is lasting. Spindle taper R8, NT30 or NT40 to fit the standard tool system.

3.One setup can complete a variety of processes such as planar, inclined surface, groove, T-shaped groove, dovetail groove, drilling, and boring.

4.The CNC system can be imported or domestic configuration according to the needs of users.

5.Optional configuration:Digital measuring ruler, pneumatic cutting tool device, high-speed infinitely variable speed milling head, worktable rotation, cooling system

specification

| Specifications | Unit | X6325 | XL6336 |

| Table size(mm) | mm | 1270*254 | 1325*360 |

| Longitudinal travel(mm) | mm | 850 | 1100 |

| Transverse travel(mm) | mm | 400 | 320 |

| Vertical travel(mm) | mm | 400 | 450 |

| Spindle speed range(rpm) | rpm | 16steps 66-4540 | |

| Quill travel(mm) | mm | 127 | |

| Quill auto feed | 003/008/0015 | ||

| Table loading(kg) | kg | 300 | |

| T slot(mm) | mm | 3/16/65 | 3/18/80 |

| Ram travel(mm) | mm | 500 | 550 |

| Ram swivel | 360(degree) | ||

| Distance between spindle center and Column(mm) | mm | 180-680 | 180-630 |

| Distance between spindle nose and Table top(mm) | mm | 0-500 | 0-450 |

| Spindle taper | NT30 | ISO40/50 | |

| Spindle motor power(kw) | kw | 2.2KW | 5.5KW |

| Head swivel | +/-45° | ||

| Head tilting | +/-45° | ||

| Machine weight (kg) | kg | 1400 | 2780 |

Product Advantages

Why choose us

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing.

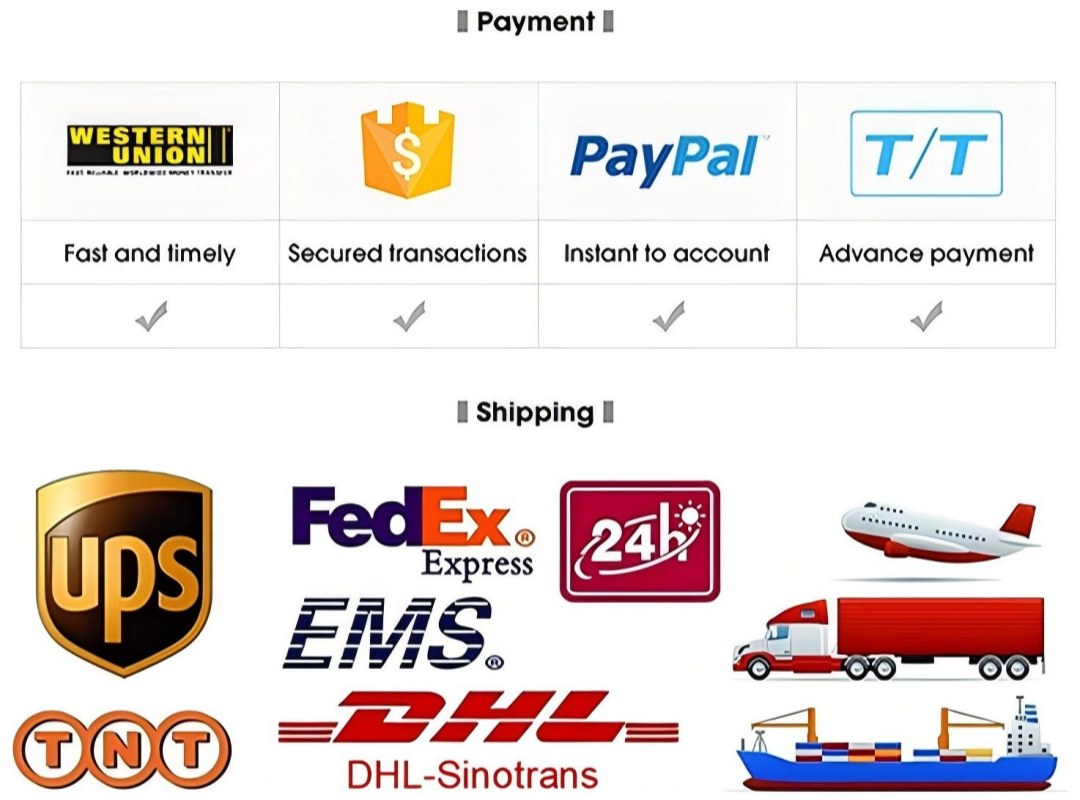

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed.

FAQ

1.How to choose the most suitable machine?

Leave A Message

Scan to Wechat/Whatsapp :