The vertical mill from Kingston Machinery is the ideal choice for those new to machining operations. It upholds the legacy of robust, cost-effective machinery designed to exceed expectations. With support for 220V, 380V, and custom voltage configurations, this machine delivers versatile operation across diverse industrial settings, making it perfectly suited for fabricators and machine shops of all sizes.

Order(MOQ) :

1Product Origin :

ChinaColor :

CustomizedShipping Port :

QingdaoLead Time :

30Weight :

4.7TonFeatures

High Efficiency and Energy Saving Industrial Milling Machine for Metal Processing

1.Table 3 axes with ball screws, high precision

2.Table feeding with 3 separate servo motors, variable speeds, not interfere each other, high reliability, easy to operate

3.Mechanical change speeds in head stock, powerful milling

4.Table with an extra supporting column, big load, high accuracy

5.Optional configuration: electric tool table, semi enclosed cover, cooling chip removal device and two-speed stepless speed regulation.

specification

|

Unit |

X5746 |

C5250 |

C5263 |

||

|

Table size |

mm |

460*1235 |

500*1600 |

500*2000 |

|

|

T-slots(NO./width/pitch) |

mm |

5*18*80 |

|||

|

Table travel (X/Y/Z) |

mm |

900*650*450 |

1200*700*500 |

1400*700*500 | |

|

Swivel angle of milling head |

- |

360° | |||

| Spindle taper |

- |

ISO40 |

ISO50 |

ISO50 |

|

|

Spindle speed range |

r.p.m |

(27)30-2050 | |||

|

Table feed(X/Y/Z) |

mm/ min |

10-1000/10-1000/6-640 |

10-1000/10-1000/5-500 |

||

|

Table rapid speed |

mm/ min |

2200/2200/1100 | |||

|

Distance between spindle nose and table surface |

mm |

50-500 |

50-550 | ||

|

Distance from spindle center line to column |

mm |

36-686 |

45-745 | ||

|

Main motor power |

Kw |

5.5 |

7.5 |

7.5 | |

|

Feed motor |

Kw |

AC servo motor X/Y:18NM; Z:27NM | |||

|

Max load |

Kg |

800 |

1800 | ||

|

Overall size |

mm |

1835*2362*2090 |

2625*2460*2080 |

2625*2860*2080 |

|

|

Weight |

Kg |

3600 |

4700 |

5000 |

|

Product Advantages

Why choose us

Mature And Stable Technology

Mature And Stable Technology

Support Customized Solutions

Support Customized Solutions

Complete After-sales Service

Complete After-sales Service

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing

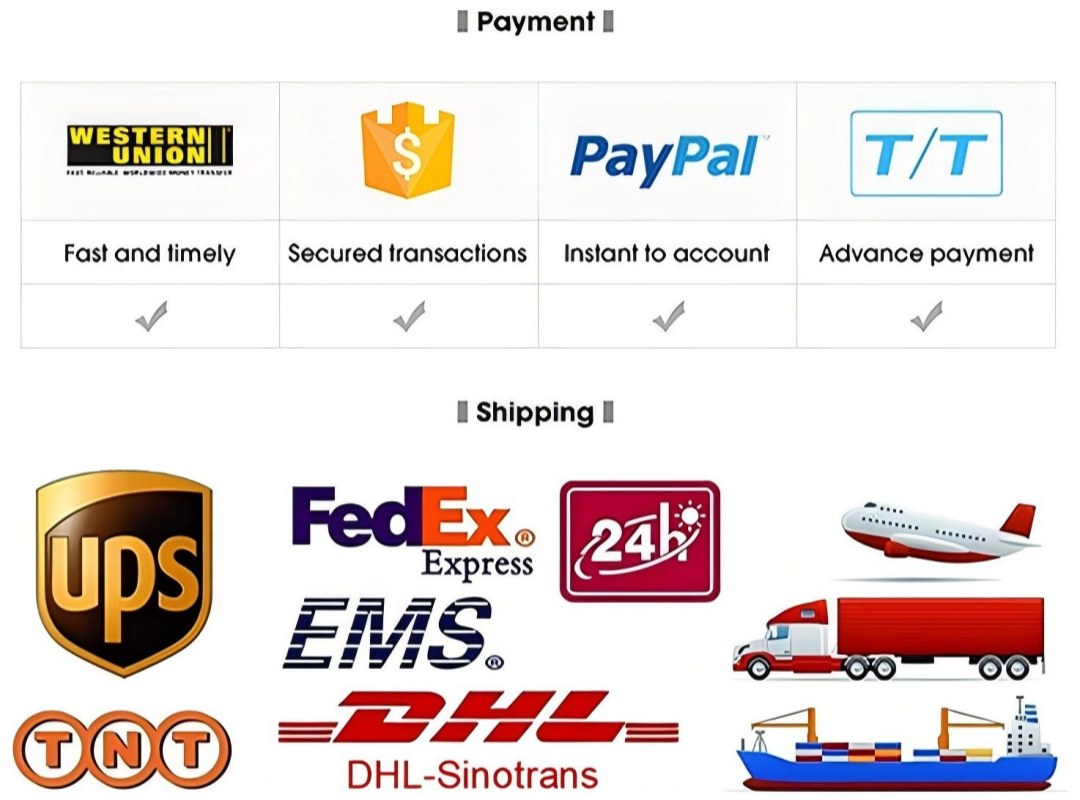

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

1. What materials can a milling machine process?

2.What is the difference between a vertical milling machine and a horizontal milling machine?

3.How to maintain a milling machine to extend its service life?

Clean daily, lubricate moving parts weekly, check/replace hydraulic oil/filters monthly.

4.Why does the milling machine produce vibration or abnormal noise during operation?

5.What factors should be considered when choosing a milling machine for batch production?

Leave A Message

Scan to Wechat/Whatsapp :