|

Pecification |

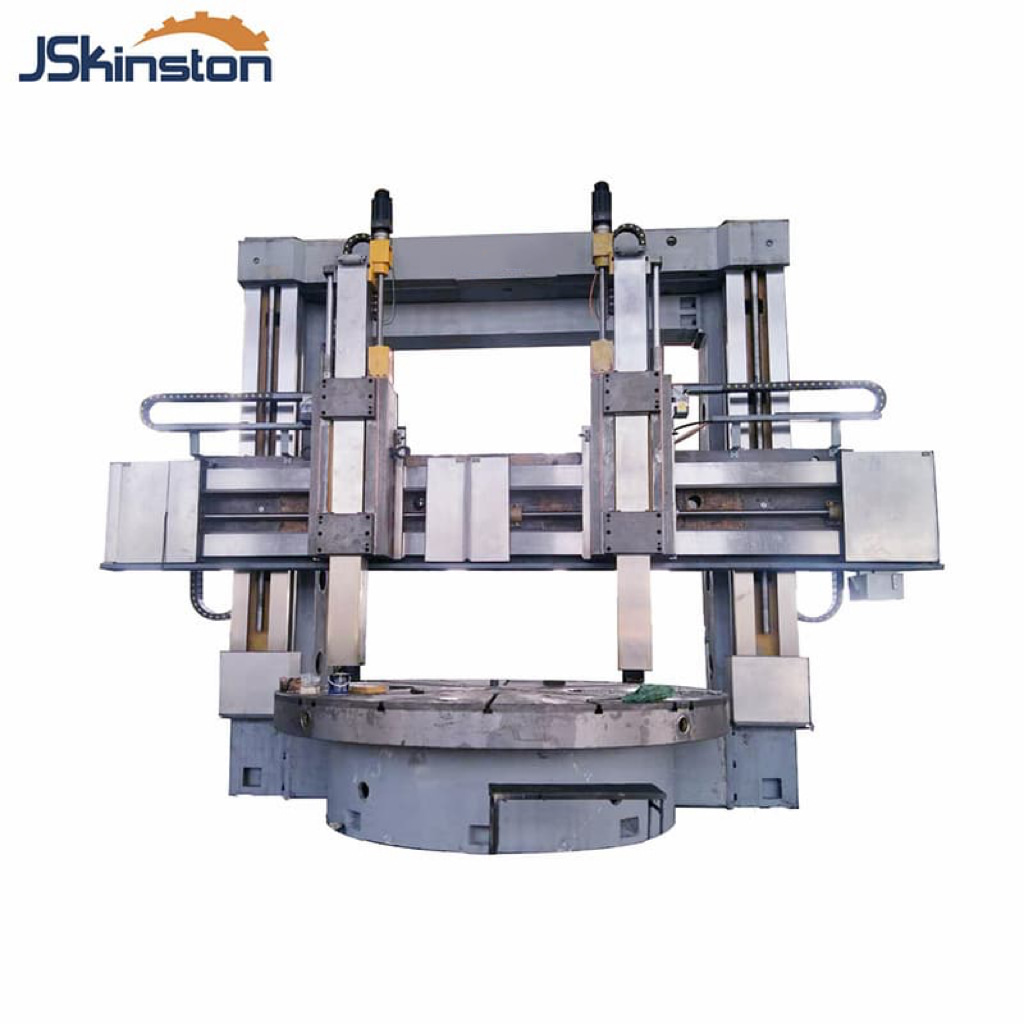

Unit Model |

C5225 |

C5231 |

C5250 |

|

|

Max dia |

mm |

2500 |

3150 |

5000 |

|

|

Table dia |

mm |

2250 |

2830 |

4500 |

|

|

Max workpiece height |

mm |

1600/2000/ 2500 |

1600/2000/ 2500 |

2500/3150 |

|

|

Max workpiece weight |

t |

10/20 |

10/20 |

65 |

|

|

Max torque of table |

KN.m |

63 |

63 |

100 |

|

|

Table rotate |

16(step) |

r/min |

2-63 |

2-63 |

0.42-42 |

|

Max cutting force of the vertical holder |

KN |

32 |

35 |

50 |

|

|

Vertical toolholder move limit |

° |

±30° |

±30° |

±30° |

|

|

Range of feed rates (18step) |

mm/ min |

0.24-145 |

0.24-145 |

0.2-145 |

|

|

Horizontal travel of rail head |

mm |

1400 |

1725 |

2765 |

|

|

Ram travel of rail head |

mm |

1000/1250 |

1000/1250 |

1250/1600 |

|

|

Fast moving speed of tool heads |

mm/ min |

1550 |

1550 |

1550 |

|

|

Knife rod cross- section size(W.D.) |

mm |

40×50 |

40×50 |

50×50 |

|

|

Main motor power |

KW |

DC/AC:55 |

DC/AC:55 |

DC/AC:90 |

|

|

Overall size of machine |

cm |

540×470 ×480/520 |

605×440 ×493/533 |

1000×700 ×723/853 |

|

|

Weight of machine |

t |

32/34/36 |

34/36/38 |

81/84 |

|

|

Ram section |

mm |

240×240 |

240×240 |

280×280 |

|