|

The vertical machining center (VMC) is an advanced manufacturing machine tool that can perform a variety of machining operations with high precision, high quality, and high surface finish. VMC-T600 vertical machining center is designed and specialized in the operations of milling, boring, drilling, tapping, etc. for small parts in one single setup. VMC-T600 is truly cost-effective and more and more popular in the machining and tooling industries.

Order(MOQ) :

1Product Origin :

ChinaColor :

CustomizedShipping Port :

QindaoLead Time :

30Weight :

5500kgFeatures

Professional Vertical Machining Center For Mold And Die Working Applications

1. Equipped with an intuitive, user-friendly CNC interface that streamlines programming and reduces setup time. The machine design facilitates quick and easy workpiece clamping, significantly minimizing programming and debugging periods. This allows operators to dedicate more time to precision machining while consistently meeting the highest quality standards.

2.The open design of the vertical machining center provides excellent visibility and accessibility, making it ideal for handling large or bulky components. It is the preferred solution for small‑batch production and geometrically simpler machining tasks, particularly suited for short‑run milling operations.

3.As one of the most widely used milling machine types, this equipment is readily available in the market and offers a competitive price advantage. The reduced acquisition cost translates into lower operational and production expenses, enabling cost savings that can be passed on to customers.

4.The machine bed is manufactured from H300 cast iron, heat‑treated for durability, with all sliding surfaces precision‑ground. A wide‑span bed base and column structure further ensure exceptional rigidity, vibration damping, and long‑term accuracy retention.

5.Each unit undergoes comprehensive testing during production and assembly, including dynamic balancing, thermal growth analysis, vibration testing, and pre‑stretching of ball screws. These procedures guarantee consistent machining accuracy and reliable performance under continuous operation.

6.The X, Y, and Z axes are equipped with large‑pitch, high‑precision, and high‑strength ball screws, enabling high feed rates while maintaining accuracy. Servo motors are directly coupled to the screws via elastic couplings, eliminating backlash and ensuring precise positioning and repeatability.

specification

|

product introduction

Why choose us

Mature And Stable Technology

Mature And Stable Technology

Support Customized Solutions

Support Customized Solutions

Complete After-sales Service

Complete After-sales Service

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing

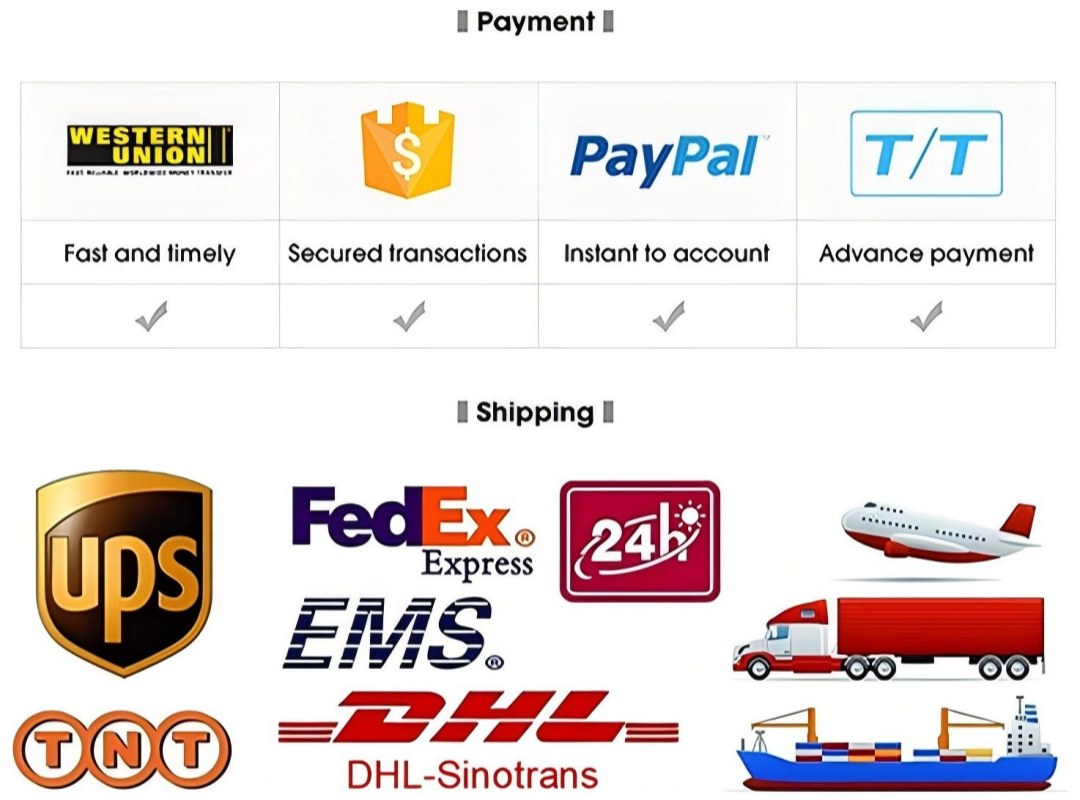

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

1. What is the weight capacity of the worktable?

Table load capacity ranges from 200 kg to 1600 kg, depending on the model, accommodating various workpiece sizes.

2. What level of precision do these machines achieve?

Positioning accuracy is up to ±0.004 mm, with repeatability up to ±0.002 mm, ensuring high-precision machining results.

3. What is included in the standard configuration?

It includes a FANUC 0i MF CNC, a 24-tool disk magazine (on most models), an 8000/10000 rpm spindle, and essential cooling/lubrication systems.

4. Can the machine be equipped for complex parts?

Yes, optional 4th/5th axis rotary tables, tool probes, and through-spindle coolant enable multi-sided and complex machining.

5. How do I choose the right model for my needs?

Select based on your required worktable size (from 700x260mm to 2000x900mm), travel distances, and workpiece weight.

Leave A Message

Scan to Wechat/Whatsapp :