Universal Manual Lathe, also known as General Horizontal Manual Lathe and Conventional Turning Lathe, is a widely used manual metal lathe for traditional machining. This universal conventional lathe is mainly used for turning external and internal cylindrical surfaces, conical surfaces, end faces, grooves, threads and various rotary parts.With stable structure, strong rigidity, easy operation and high reliability, this general purpose manual lathe features high machining accuracy and good durability. It is suitable for single-piece, small-batch production and maintenance work, and can meet different metal processing requirements in machinery manufacturing.

Order(MOQ) :

1Product Origin :

ChinaShipping Port :

ShanghaiLead Time :

40Weight :

2295kgFeatures

Easy-Operate Versatile Metal Cutting and Shaping Universal Lathe

The High Precision Heavy Duty CNC Vertical Lathe, also known as a heavy-duty vertical turning machine, is a widely used CNC metal lathe for efficient heavy-duty machining. This heavy-duty vertical lathe is mainly used to process large-diameter, short-length heavy workpieces, such as discs, rings, hubs, and other heavy rotary parts, while also performing end face turning, grooving, threading, and other processes. Its vertical spindle structure features strong load capacity, high rigidity, and stable machining accuracy, with convenient workpiece clamping and high production efficiency. It is widely applied in wind power, metallurgy, engineering machinery, molds, automotive parts, and other industries, making it an ideal choice for machining heavy workpieces that are difficult to clamp on horizontal lathes.

specification

| Specification |

Model |

|||||

|

C6241 |

C6246 |

C6246E |

C6251 |

C6256 |

C6256E |

|

|

Swing over bed |

410mm(16”) |

460mm(18”) |

460mm(18”) |

510mm(20”) |

560mm(22”) |

560mm(22”) |

|

Swing over cross side |

220mm(8-13/16”) |

270mm(10-3/4”) |

270mm(10-3/4”) |

302mm(12”) |

355mm(14”) |

355mm(14”) |

|

Swing in gap diameter |

640mm(25-1/8”) |

690mm(27-1/8”) |

690mm(27-1/8”) |

735mm(28-7/8”) |

785mm(30-7/8”) |

785mm(30-7/8”) |

|

Distance between centers |

1000mm(40”) |

1000mm(40”) |

||||

|

1500mm(60”) |

1500mm(60”) |

|||||

|

2000mm(80”) |

2000mm(80”) |

|||||

|

|

3000mm(120”) |

|||||

|

Valid length of gap |

165mm(6-12”) |

170mm(6-11/16”) |

||||

|

Width of bed |

300mm(11-13/16”) |

350mm(13-13/16”) |

||||

|

Spindle nose |

D1-6 |

D1-8 |

D1-8 |

|||

|

Spindlebore |

58mm(2-1/4”) |

80mm(3-1/8”) |

80mm(3-1/8”) |

105mm(4-1/8”) |

||

|

Taper of spindle bore |

No.6 Morse |

No.7 Morse |

No.7 Morse |

φ113(1:20) |

||

|

Range of spindle speed |

12changes,25~2000r/min |

12 changes,25~2000r/min |

12 changes, 25~1500r/min |

|||

|

Compound rest travel |

28mm(5”) |

130mm(5-1/8”) |

||||

|

Cross slide travel |

285mm(11-1/4”) |

316mm(12-7/16”) |

||||

|

Max.section of tol |

25×25mm(1”×1”) |

|||||

|

Lead screw thread |

6mm or 4T.P.I. |

|||||

|

Longitudinal feeds range |

42 kinds,0.031-1.7mm/rev(0.0011”-0.0633”/rev) |

3k nde 0059-1.646mmrev(0.0022-0.0612”/rev) |

||||

|

Cross feeds range |

42 kinds,0.014-0.784mm/rev |

42 kinds,0.020-0.573mm/rev |

||||

|

(0.00033”-0.01837”/rev) |

(0.00048”-0.01354”/rev) |

|||||

|

Threads metic pitches |

41 kinds,0.1~14mm |

47 kinds,0.2~14mm |

41 kinds, |

|||

|

0.1-14mm |

||||||

|

Threads imperial pitches |

60 kinds,2~112T.PI. |

|||||

|

Threads diametral pitches |

50kinds,4~112DP |

|||||

|

Threads module pitches |

34 kinds,0.1~7MP |

|||||

|

Qull diameter |

60mm(2-5/16”) |

75mm(2-15/16”) |

||||

|

Quiltravel |

130mm(5”) |

180mm(7-1/16”) |

||||

|

Qull taper |

No.4 Morse |

No.5 Morse |

||||

|

Main motor power |

5.5KW(7.5HP)3PH |

7.5KW(10HP)3PH |

||||

|

Coolant pump power |

0.1KW(1/8HP)3PH |

|||||

|

Overall |

220×108×134cm |

220×108×137cm |

220×108×137cm |

239×115×143cm |

239×15×146cm |

239×15×146cm |

|

dimension(L×W×H) |

275×108×134cm |

275×108×137cm |

275×108×137cm |

284×115×143cm |

284×115×146cm |

284×115×146cm |

|

|

325×108×134cm |

325×108×137cm |

325×108×137cm |

334×115×143cm |

334×115×146cm |

334×115×146cm |

|

|

|

|

|

434×115×143cm |

434×115×146cm |

434×115×146cm |

|

Packing size(L×W×H) |

225×112×162cm |

225×112×162cm |

225×12×162cm |

245×119×174cm |

245×119×174cm |

245×119×174cm |

|

280×112×162cm |

280×112×156cm |

280×112×156cm |

290×119×174cm |

290×119×174cm |

290×119×174cm |

|

|

330×112×162cm |

330×112×156cm |

330×113×156cm |

340×119×174cm |

340×19×174cm |

340×119×174cm |

|

|

|

|

|

440×119×174cm |

440×119×174cm |

440×19×174cm |

|

|

Net weight |

1580kg |

1645kg |

1645kg |

2070kg |

2195kg |

2195kg |

|

1745kg |

1810kg |

1810kg |

2160kg |

2285kg |

2285kg |

|

|

1900kg |

1965kg |

1965kg |

2435kg |

2560kg |

2560kg |

|

|

|

|

|

2805kg |

2930kg |

2930kg |

|

|

Gross weight |

1844kg |

1910Kg |

1910kg |

2460kg |

2600kg |

2600ko |

|

2049kg |

2115kg |

2115kg |

2550kg |

2690kg |

2690kg |

|

|

2229kg |

2295kg |

2295k9 |

2840kg |

2980kg |

2980kg |

|

|

|

|

|

3270kg |

3410kg |

3410kg |

|

product introduction

Why choose us

Mature And Stable Technology

Mature And Stable Technology

Support Customized Solutions

Support Customized Solutions

Complete After-sales Service

Complete After-sales Service

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing

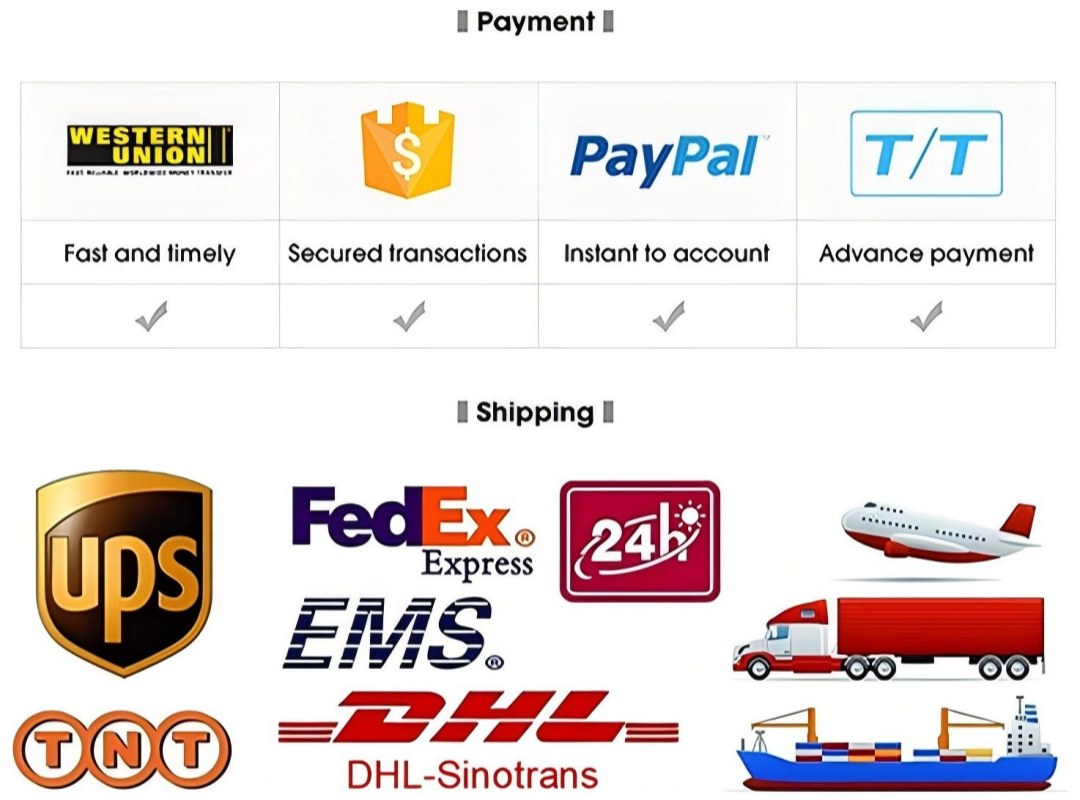

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

1.What workpieces can this universal lathe process?

It handles turning, threading, and various rotary parts.

2.Is this lathe easy to operate for beginners?

Yes, with intuitive controls and clear operation guides.

3.Is regular maintenance for this lathe complicated?

It delivers high precision for stable, reliable results.

4.Is regular maintenance for this lathe complicated?

No, simple routine checks and lubrication suffice.

5.What production types is this lathe suitable for?

Ideal for single-piece and small-batch production.

Leave A Message

Scan to Wechat/Whatsapp :