This Heavy Duty Precision Industrial Universal Lathe boasts superior heavy cutting performance and high structural rigidity for industrial metal processing. We provide factory direct sales with MOQ 1 set, one-year warranty and on-site technical training for installation and maintenance.

Order(MOQ) :

1Product Origin :

ChinaShipping Port :

ShanghaiLead Time :

40Weight :

4495kgFeatures

Heavy Duty Precision Industrial Universal Lathe

The Heavy Duty Precision Industrial Universal Lathe is a professional metal processing equipment tailored for industrial heavy-duty machining scenarios, with outstanding processing capacity and stable operation performance. This industrial universal lathe is widely applicable to processing various rotary parts such as discs, shafts and ring parts, and fully meets the diverse machining needs of mechanical processing enterprises in different industries.

specification

|

SPECIFICATIONS |

MODEL |

|

Capacity |

C6266*3000 |

|

Max. swing over bed |

660mm(26”) |

|

Max. swing over slide |

440mm(17-5/16”) |

|

Swing in gap diameter |

900mm(35-7/16”) |

|

Valid length of gap |

250mm(10”) |

|

Bed width |

400mm(15-13/16”) |

|

Spindle nose |

D1-8 |

|

Spindle bore |

105mm(4-1/8”) |

|

Range of spindle speed |

25-1600r/min |

|

Max.travel of compound rest |

230mm(9-1/8”) |

|

Max.travel of cross slide |

368mm(14-1/2”) |

|

Leadscrew thread |

12mm or 2T.P.I |

|

Max.section of tool |

25x25mm(1”x”1) |

|

Longitudinal feeds range |

0.044-1.48mm/rev(0.00165”-0.0550”/rev) |

|

Cross feeds range |

0.002-0.74mm/rev(0.00083”-0.02774”/rev) |

|

Inch threads range |

54kinds,7/16-80T.P.I |

|

Diametrical pitches range |

42kinds,7/8-160DP |

|

Module pitches range |

46kinds,0.25-60MP |

|

Quill diameter |

90mm(3-1/2”) |

|

Quill travel |

235mm(9-1/4”) |

|

Quill taper |

No.5Morse |

|

Main motor power |

7.5kw(10HP)3HP |

|

Overall dimension (LxWxH) |

4710x1230x1600 |

product introduction

Why choose us

Community charging overall solution covers all application

Mature And Stable Technology

Mature And Stable Technology

Support Customized Solutions

Support Customized Solutions

Complete After-sales Service

Complete After-sales Service

--

our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing

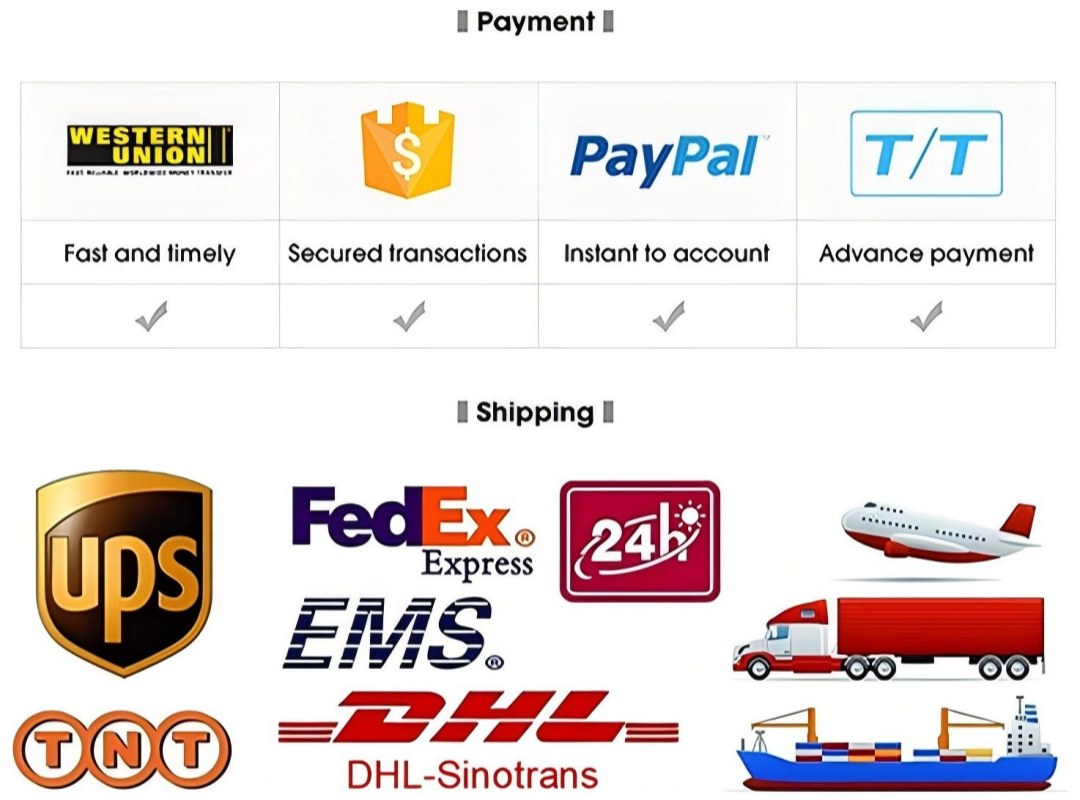

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

1.What is the max swing over bed of this lathe?

Max swing over bed is 660mm, gap swing diameter 900mm.

2.What is the main motor power of the lathe?

Equipped with 7.5kw high-power main motor for heavy cutting.

3.How long is the warranty period of this product?

We provide one-year warranty for the industrial universal lathe.

4.What is the MOQ and delivery time of the lathe?

MOQ 1 set, delivery in 40 working days after advance payment.

5.Do you provide technical training for the lathe?

Yes, on-site training for installation, use and maintenance is available.

Leave A Message

Scan to Wechat/Whatsapp :