Surface grinder is a kind of high-precision metal cutting machine tool. The workpiece plane is slightly grinded by a high-speed rotating grinding wheel to obtain extremely high flatness, parallelism and surface finish. This series machine tool adopts the horizontal axis and moment table structure, the table moves smoothly and reciprocally under the hydraulic system drive, the spindle is rigid and the rotary precision is high, which is the core equipment of the machining workshop to realize the precision plane forming.

Order(MOQ) :

1Product Origin :

ChinaColor :

CustomizedShipping Port :

ShanghaiLead Time :

30Weight :

84TonFeatures

High Production Surface Grinder Machine For Sale

1.The main castings of this machine are all made of cast iron material. After annealing treatment, internal stress is eliminated to ensure high precision, high rigidity and prolong the service life of the machine.

2.The spindle adopts precision angular contact ball bearing, high rotation precision, stable and reliable long-term operation. The guide rail is quenched with high frequency and precision grinding, good wear resistance and long accuracy retention.

3.Not only do we offer high-quality surface grinding machines, but we also provide comprehensive process solutions. From equipment selection, installation and commissioning, operation training to after-sales maintenance, we ensure that each machine can maximize its value in your workshop.

4.Standard electromagnetic chuck, the workpiece clamping fast and firm. The fully enclosed protective cover and interlock switch comply with international safety standards.

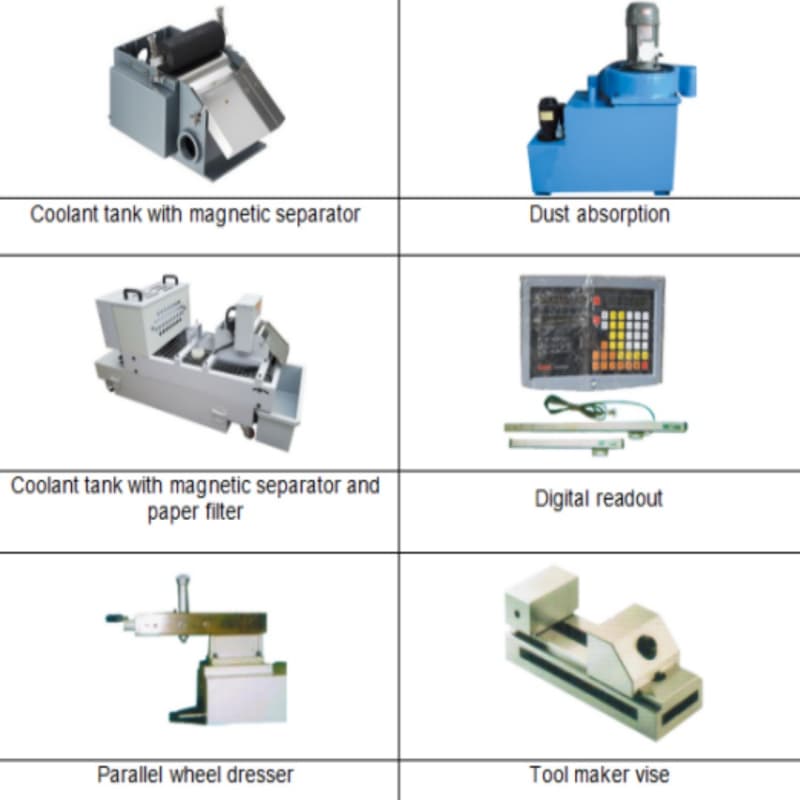

5.Optional configuration:Fully closed loop grating scale feedback system to achieve micron level positioning accuracy; Automatic dressing device, online measuring device to achieve unmanned mass production.

specification

| Pecification | Unit | KST614 | KST618 | |

| Processing capacity | table size | mm | 150*350 | 150*450 |

| max. grinding length | mm | 370 | 470 | |

| max. grinding width | mm | 160 | ||

| distance from table surface to spindle center | mm | 400 | ||

| permanent magnetic chuck | mm | 150*300 | 150*460 | |

| Left and right feed | manual stroke | mm | 360 | 460 |

| Front and back feed | manual feed(per scale) | mm | 0.02 | |

| manual feed(per revolution) | mm | 5 | ||

| Up and doen feed | manual feed(per scale) | mm | 0.005 | |

| manual feed(per revolution) | mm | 1 | ||

| Wheel | wheel size | mm | 180*16*32 | |

| spindle speeds | rpm | 3600/3000 | ||

| Motor | spindle motor | rpm | 1.5HP 60HZ/3600rpm | |

| Weight | gross | kgs | 690kgs | 850kgs |

product introduction

Why choose us

--

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

1.What is the main processing purpose of a grinding machine?

It is a high-precision finishing equipment, mainly used for precision grinding of workpiece surfaces (flat, cylindrical, conical, curved surfaces, etc.), to improve the surface finish and dimensional accuracy of workpieces. It is suitable for the finishing process of precision parts in aerospace, auto parts, mold, bearing and precision machinery industries.

2.What common types of grinding machines do you supply?

We provide a full range of mainstream grinding machine models for different processing needs: surface grinding machine, cylindrical grinding machine, internal grinding machine, centerless grinding machine and CNC precision grinding machine. CNC models support automatic grinding and multi-process linkage for complex precision parts processing.

3.Can the grinding machine realize automatic production and connect with the assembly line?

Yes. Our CNC grinding machines support automatic feeding, automatic grinding and automatic unloading configuration, and can be equipped with feeding robots, conveyors and other auxiliary equipment according to the production line needs, to realize full-automatic unmanned grinding production and match the whole factory assembly line operation.

4.What grinding materials and grinding wheels are suitable for your grinding machine?

Our grinding machines are compatible with common grinding materials such as steel, stainless steel, aluminum alloy, copper alloy, ceramic and hard alloy. We can match customized grinding wheels (corundum, silicon carbide, diamond grinding wheels) according to the workpiece material and processing requirements, and provide professional grinding wheel selection guidance.

5.What are the key points of daily operation and maintenance of the grinding machine?

Grinding wheel maintenance: Check the grinding wheel for cracks before use, and perform dynamic balance calibration regularly to avoid vibration during operation;

Lubrication: Timely add special lubricating oil to the guide rail, spindle and lead screw to ensure smooth movement of the slide seat;

Cleaning: Clean the grinding debris and coolant residue on the worktable and grinding head after each operation;

Precision inspection: Calibrate the grinding precision of the equipment every 1-3 months

Leave A Message

Scan to Wechat/Whatsapp :