CNC gear hobbing machine is a special high-precision automatic gear processing machine tool, which can efficiently process cylindrical gears, helical gears, worm gears and other workpieces. It features high rigidity, stable operation, high machining accuracy and strong durability, ideal for batch precision machining and large-scale production of various gears.

Order(MOQ) :

1Product Origin :

ChinaColor :

OptionalShipping Port :

ShanghaiLead Time :

30Weight :

6800kgFeatures

Raised height of vertical column and increased stroke effectively expand the working range.

* Mechanism with electric tool leap allows longer hob and greatly increases service life of

the cutting tool .

* Worm gear of a high precision over five grade features long service life and steady accuracy.

* Traditional bearings along the hobs are replaced with rolling bearings to enable greater speed of the tools.

* External support of the small column tailstock adopts the hinge structure and can be easily opened outward, convenient to hang components of large diameters.

specification

|

Specification |

YK/YKD3150CNC6(4) |

unit |

|

Maximum workpiece diameter |

500 |

mm |

|

Maximum modulus |

10 |

mm |

|

Helical angle of machined helical gear |

±45° |

° |

|

Maximum diameter of installed hobbing cutter |

160 |

mm |

|

Maximum length of installed hobbing cutter |

160 |

mm |

|

Maximum axial movement of hobbing cutter |

100 |

mm |

|

Replaceable mandrel diameter hobbing cutter |

22 27 32 40 |

mm |

|

Conicity of hobbing cutter spindle taper bore |

MT5# |

mm |

|

Horizontal distance from t center of hobbing cutter to center of worktable |

25-330 |

mm |

|

Vertical distance from center of hobbing cutter to surface of worktable |

235-535 |

mm |

|

Distance from rear column center to worktable surface |

350-700 |

mm |

|

Diameter of worktable surface |

510 |

mm |

|

Maximum speed of hobbing cutter spindle |

625 |

rpm |

|

Axial feeding speed range (Z- axis) |

0-2000 |

mm/ min |

|

Radial feeding speed range (X-axis) |

0-2000 |

mm/ min |

|

Maximum tangential motion speed |

2000 |

mm/min |

|

Maximum speed range of worktable |

30 |

rpm |

|

Maximum rotating speed of tool post |

4.5 |

o/s |

|

Machine volume (L x W x H) |

2.97x1.80x2.15 |

m |

|

Weight of machine |

5500/6800 |

kg |

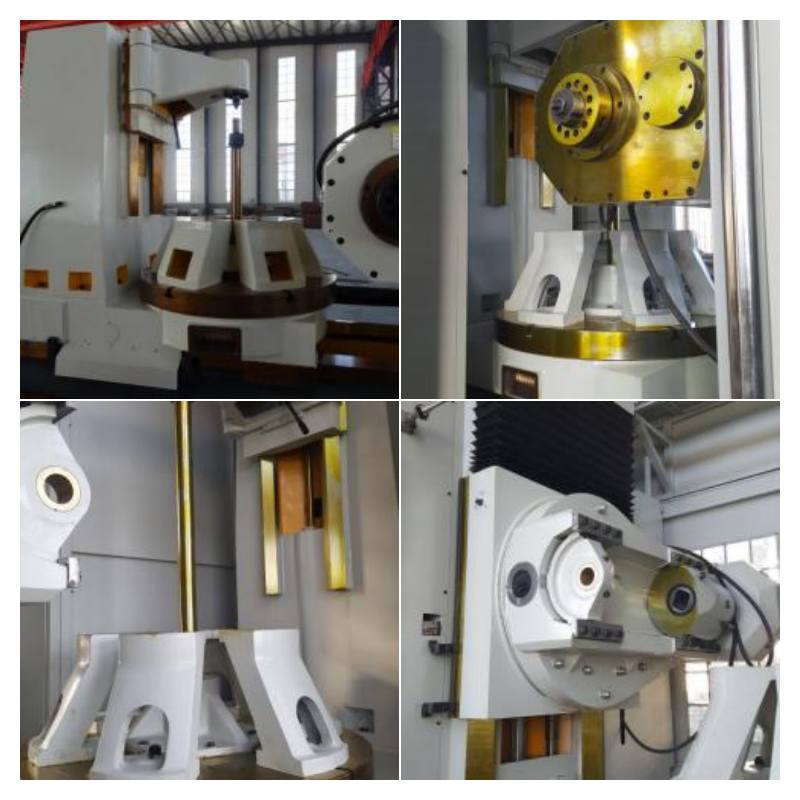

product introduction

Performance of this machine:

1. Raised height for vertical column and increased stroke: The vertical column is made higher (180mm increased axial stroke in head slide than YK3180 of the same kind ) to enable processing of larger tooth width.

2. Service life of cutting tools is increased by electric tool leap. The longest stroke reaching 180mm, such electric tool leap takes longer hob and greatly increases life the hob.

3. High precision and long service life: The machine adopts the worm gear of a high precision over five grade and uses bronze alloy material which is of high abrasion resistance, enabling long service life and steady accuracy.

4.Higher toolspeed allowed: Rolling bearings replace the traditional bearings along the hobs to allow greater rotating speed of the tools.

5. Backlash balancing cylinder is involved as the tool post moves in the axial direction, effectively reducing the space between lead screws and eliminating vibration.

6. Convenient hydraulic powered structure reduces the non-cutting time as well as the times to use the cutting tools.

7. External support of the small column tailstock adopts the hinge structure and can be easily opened outward, convenient to hang components of larger diameters.

Why choose us

Our certification

Authoritative Certifications, Stable and Reliable Quality.

factory show

Professional Production Base, Strength in Precision Manufacturing

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

Leave A Message

Scan to Wechat/Whatsapp :