This machine is mainly used for milling holes for large and medium-sized parts as well as other processing such as hole drilling, expanding, reaming and plane milling. The radial tool post of facing head can be used for surfacing; if cooperated with rotary work table, it can be used for processing inner hole and outer circle with large diameter and short length. facer is installed on boring rod, which can be applied to the processing of workpiece plane milling. Bed of TX6216E/1、TX6216E/2 machine is a lengthened type.

Order(MOQ) :

1Product Origin :

ChinaColor :

CustomizedShipping Port :

ShanghaiLead Time :

30Weight :

67tonFeatures

Use and features of TX6216E series of floor type boring machine

1.Main transmission system

The main transmission of the TX6216E uses a DC motor for stepless speed regulation, plus 4 mechanical speed stages controlled by a handle. Spindle rotation can be reversed via the motor.

2.Facing head drive

The facing head rotates with the hollow spindle (powered by an end face key) and drives the radial slide feed through a planetary mechanism. It adopts backlash‑free transmission to avoid “cutter falling”.

3.Other movements

AC motors drive spindle axial movement, facing head radial tool post movement, headstock vertical movement, and front column longitudinal movement. Stepless speed is obtained by mechanical speed stage Ⅱ plus electric speed regulation, controlled by electromagnetic clutches (only the facing head radial tool post uses a hydraulic clutch). All movements can be reversed by the motor.

4.Sliding carriage

The sliding carriage is fitted with a clamping device for convenient, reliable operation and lower labor intensity.

5.Guideways

Sliding carriage and headstock guideways are inlaid with soft bands to reduce static and dynamic friction coefficients and ensure stable running.

6.Transmission structures

Column movement is driven by gear and rack; headstock and boring rod movement use lead screw and nut.

7.Lubrication & protection

The hydraulic lubrication system uses top‑brand domestic hydraulic parts. Guideways and lead screws are automatically lubricated. The bed guideway is equipped with a stainless steel shield.

specification

|

Spindle |

|

| Diameter |

Φ160mm |

|

Taper hole |

Metric 80 |

|

Rotation (stepless) |

1.8~500r/min |

|

Feed range (stepless) |

0.45~1500mm/min |

|

Maximum axial travel |

1200mm |

|

Rapid speed |

1500mm/min |

|

Distance from spindle centre to platform (min.) |

600mm |

|

Max. |

3600mm |

|

Maximum diameter of boring hole |

Φ750mm |

|

Maximum resistance force of feed |

3920kg |

|

Maximum tightening torque |

490kg.m |

|

Radial tool post of facing head |

|

|

Rotation (stepless) |

1.8~120r/min |

|

Feed range (stepless) |

0.21~750mm/min |

|

Maximum travel |

220mm |

|

Rapid speed |

750mm/min |

|

Maximum diameter of face turning |

Φ1000mm |

|

Maximum diameter of boring hole |

Φ1000mm |

|

Headstock |

|

|

Maximum vertical travel (Y axis) |

3000mm |

|

Feed range (stepless) |

5~1500mm/min |

|

Rapid speed |

1500mm/min |

|

Front column |

|

|

Maximum horizontal travel (X axis) |

8000mm |

|

Feed range (stepless) |

5~1500mm/min |

|

Rapid speed |

1500mm/min |

|

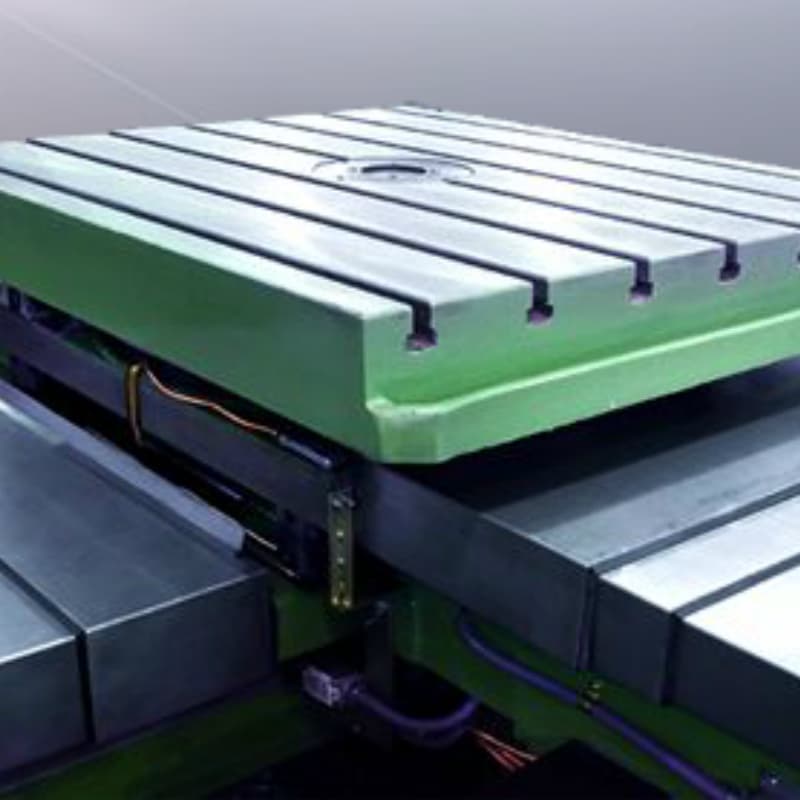

Platform (Special ordered) |

|

|

Dimension of platform |

4500×1800×400 |

|

Area (length ×width) |

5400×4500mm |

|

Maximum loading capacity |

15t/㎡ |

|

Power |

|

|

Main motor Z4-160/31 |

30KW 1500r/min |

|

Feed motor |

7.5KW 1500r/min |

|

Overall dimension (length × width × height) |

12600×8802×7000mm |

|

Overall weight(about) |

67t |

Product Advantages

Why choose us

Our certification

Authoritative Certifications, Stable and Reliable Quality.

--------------占位---------------

--------------占位---------------

factory show

Professional Production Base, Strength in Precision Manufacturing

Packing and shipping

Safe & Professional Transportation, On-Time Delivery Guaranteed

FAQ

Leave A Message

Scan to Wechat/Whatsapp :